Supply

Chain

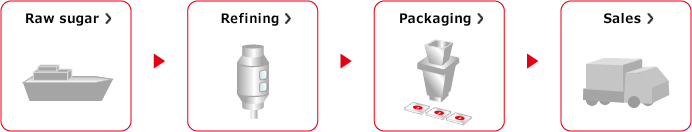

Building an integrated supply chain

"Cup brand" sugar is made by refining raw sugar procured in Japan and abroad.

In addition to small packages for household use and large packages for commercial use, we deliver to customers in a varied range of formats including stick-shaped packages and individual portions.

With its network of Group companies, the Nissin Sugar Group has built an integrated supply chain extending from the supply of raw sugar to refining, packaging and sales.

Raw sugar

The raw material for sugar is raw sugar, which is made by extracting and then crystallizing the juice or sugar content from sugarcane or sugar beet.

The raw material may be imported raw sugar or domestically produced raw sugar. Cup brand sugar is produced by refining these materials.

Nakatane Factory (Shinko Sugar Mill Co., Ltd., Kagoshima)

Nakatane Factory (Shinko Sugar Mill Co., Ltd., affiliate company) is located on Tanegashima Island (Kagoshima), the northernmost sugarcane cultivation site in Japan. It manufactures raw sugar from locally grown sugarcane.

The raw sugar is supplied to our factories.

Refining

The raw material is refined at our factories to manufacture various types of sugar.

Imafuku Factory (Osaka)

The West Japan production location for "Cup brand" products, this factory has a production capacity of 120,000 tons a year. It is the only factory in Japan to produce both refined sugar and rock sugar.

Acquisition of FSSC22000 certification

Shin Higashi Nihon Sugar Manufacturing Co., Ltd. (Chiba),

joint production factory

The East Japan production location for "Cup brand" products, this factory has a production capacity of 350,000 tons a year. It also has a dedicated wharf for receiving raw sugar, with ability to dock 45,000 ton-class large ships.

Acquisition of FSSC22000 certification

Liquid sugar

These factories also manufacture liquid sugar for commercial use.

Under a stringent system of hygiene management, the composition, concentration and other properties are finely adjusted in line with the requirements of the customer product. The product is delivered by tanker truck.

Packaging

After refining at our factories, the sugar is packaged in various weights and formats depending on supplier and consumer requirements.

Sugar is also subjected to secondary processing at specialized factories to produce a wide range of sweetener products.

Chiba Factory (Chiba)

Granulated sugar, low-calorie sweetener, and other sweetener products are transferred here to smaller packages to create products with high added value.

Acquisition of FSSC22000 certification

Acquisition of FSSC22000 certification

Sales

The products manufactured at our factories are sent to our sales offices and distribution centers, from where they are delivered to customers throughout Japan.

Our sales offices are located in six major cities across Japan to ensure nationwide reach.

Our products are delivered through various channels including direct factory dispatch and distribution through the Chiba Distribution Center or one of our other regional distribution centers.